This report describes the supply of BNF technology products by the N2Africa Project in Kenya during the 2017 long rains. This is the penultimate growing season of our activities in Kenya, and one that undertook a difficult transition from the grassroots focus of the past to an agribusiness orientation. We now work with agrodealers and input suppliers through the One Stop Shop Operation Mechanism (OSSOM, sounds like ‘awesome’) as a key component of our N2Africa Project exit strategy in a manner that reinforces commercial supply of BNF technology products to farmers in West Kenya beyond the lifespan of the project. In the past recommendations were made concerning which products should be used by farmers, and in what proportions, and we developed a test-marketing approach to find out how well they translate within a commercial context. This activity was slightly rushed because funds were released the same month that OSSOM was launched (February 2017). Nevertheless, a rigorous input supply effort was started, in large part through our solid working relations with product suppliers, namely SeedCo and MEA Fertilizers. Also central to our approach is quality assurance of legume inoculants, largely through testing by the University of Nairobi Microbial Resource Center (MIRCEN). This laboratory not only conducts routine tests of biofertilizers used in Kenya, but continues to evaluate elite rhizobial strains identified during Phase I of the N2Africa Project.

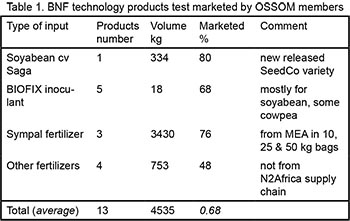

One of the first tasks of OSSOM was to test market BNF technology products among OSSOM members. To do this, soyabean seed, legume inoculants and blended legume fertilizers were purchased from commercial suppliers and distributed to members who then maintained standardized sales records. Results were compiled and interpreted both in terms of product sales and member success in marketing these products. Overall, 13 products totaling over 4.5 tons were test-marketed. There was reasonable balance between the sales of soyabean seed, BIOFIX legume inoculant and recommended Sympal fertilizer. This suggests that farmers are buying into the N2Africa recommendations and are also ready to invest in seed of new soyabean varieties as they appear in the market. Test-marketing also included some fertilizers not provided by the OSSOM supply chain and sales of these non-recommended fertilizers was considerably less.

| Eight agrodealers were provided with three input products (Saga seed, BIOFIX for soyabean and Sympal fertilizer) totaling 204 kg and were encouraged to carry additional inputs as well. Four out of eight only reported test-marketing of products they had received through the OSSOM supply chain. One of these, AFDB, failed to establish their new shop in time for test-marketing and was excluded from further analysis. Three of the agrodealers placed large additional orders with MEA Ltd. and tested marketed inoculants and fertilizers far in excess of what was provided through OSSOM. On average, each of these agrodealers test marketed 567 kg of five different BNF technology products, with 75% of this volume sold in the few weeks before the onset of the 2017 long rains growing season. This sort of success bodes well for the commercial delivery of BNF technologies in the future and is central to the N2Africa-Kenya exit strategy. |

|

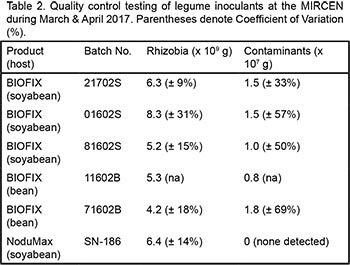

Testing of BIOFIX legume inoculants continues at the University of Nairobi MIRCEN laboratory. Quality assurance tests were conducted for several different host products (e.g. Desmodium, green gram, pea and alfalfa) but in this report we focus primarily on results for soyabean and bean (Table 1). Tests were performed by drop plating Congo Red YMA following N2Africa protocols. As with previous reports of BIOFIX quality control, the rhizobia exceed the minimum standard (Colony Forming Unit > 1 x 109 per gram) but the contamination threshold is consistently exceeded as well. Nevertheless, the manufacturer indicated that contamination levels are decreasing because they have started to autoclave the carriers twice in an industrial device. Visual inspection of plates reveals that contaminants are mostly Actinomycetes rather than other bacteria or fungi. Clearly the BIOFIX ordered by the One Stop Shops and others for the 2017 Long Rains contain adequate rhizobia, but contaminants may pose a hazard to product storage in absence of refrigeration. Again the MIRCEN laboratory kindly agreed to test a batch of NoduMax (SN-186) from Nigeria. Despite being a few months old, the sample contained large numbers of USDA 110 (bv. BioNext Tiny) and no contaminants (Table 2).

|

|

|

The transition from grassroots to agribusiness focus during Kenya’s final year is proceeding with reasonable success. OSSOM members enthusiastically embraced this opportunity, and several farmer groups are prepared to privatize their input supply to members. OSSOM slightly underperformed in terms of product marketing and in completion of the recently developed M&E tools (more on this in future reports). Nonetheless, the test-marketing exercise was largely a success and it indicated that customers are purchasing BNF technology products in a proportionate manner. Furthermore, OSSOM members are making separate arrangements with BNF technology product suppliers. MIRCEN continues to perform well in its inoculant quality assurance duties and all tested inoculants met threshold rhizobial targets, but the BIOFIX product continues to harbor excessive contaminants. Finally, elite strains for soyabean identified during Phase I continue to perform well in field tests and perhaps the development of a mixed strain inoculant product should be considered.

Paul L. Woomer, Nancy K. Karanja, Welissa Mulei and Josephine Ongoma