During March 2012, while surfing the web for information about inoculants in Africa, I read in N2Africa Podcaster # 12 that "the N2Africa proposed strategy suggested was "to import high quality inoculants, and focus on ensuring an effective supply chain for inoculants in the areas where N2Africa is working until we know that there is sufficient demand to warrant local production". I wrote an email to Dr. Ken Giller offering him samples for trials and since then we have been mailing from time to time. Recently, he asked me to write a small report on what we are doing in Africa. My idea is to set a comparison between the development of inoculants in my country and what N2Africa is doing.

During the decade of 1950, the Uruguayan government had designed a strategy to improve our natural pastures. By those days, New Zealand and Australia were already leaders in the seed industry so scientists from their National Research Institutions were invited to visit the country in order to make a diagnosis of the pasture situation. Their opinion was that Uruguay should incorporate more legumes in order to have better food for cattle, so farmers could increase milk and meat production.

National researcher Dr. Alberto Boerger was searching for someone who could help him to introduce specific symbiotic Rhizobium, for the legumes he was studying, in order to allow them fix nitrogen from the air. During 1956, he asked Laboratorios Dispert if they could supply him specific inoculants for alfalfa, clovers and lotus. Dr. Carlos Batthyany, Dispert´s microbiologist, started analysing the project, and asked ATCC and Australian Labs to send them several recommended strains for the target legumes and simultaneously isolated native strains to be identified as specific or not. After selecting the most suitable strain for each legume, Dispert started the scaling, that ended in year 1963 in a 750 litres fermenter which allowed them to have good inoculant productivity.

|

Photo 1: Left to right: Pedro Lage, Prof. Yaacov Okon, Microbiologist Cecilia Herrmann, Microbiologist Emilia Monteleone, Prof. Carlos Labandera-Gonzalez at Lage & Cía.´s facilities in Montevideo, Uruguay |

During the 1960s, the Ministry of Agriculture created the "Plan Agropecuario Institute" (MA-PAI) which had in its structure the Soil Microbiology and Inoculant Control Laboratory (SMICL) in order to verify the quality of the inoculants delivered to the market. Dr. Carlos Batthyany accepted the invitation to be it’s first Director. He asked Dr. Richard Date to establish the first protocols for inoculant control and had the initiative to train local human resources, so he sent Agronomist Carlos Labandera to take his MSc degree in Soil Microbiology in Australia. Immediately after coming back, Prof. Labandera conducted Soil Microbiology courses at our University.

|

The SMICL set the initial standards for inoculants in more than 1x108 viable cells per gram when produced and more than 1x107 viable cells per gram of inoculant at expiry date. During each legume planting season MA-PAI sent several agronomists to prepare meetings in order to train farmers in the new inoculation technology: how to keep the inoculants, dosage and preparation of the slurry for seed treatment, maximum time to plant the inoculated seeds, etc. Another important point to note is that our National Bank was encouraged by the Government to offer very low rate loans to enhance the purchase of legal seed with proper germination and free of weeds, fertilisers and inoculants. The money was not given to the farmer: the bank paid the distributor that sold him any of the products in order to ensure that the money would be spent in improving the pastures.

Due to this strategy, Uruguay multiplied its cattle and dairy productivity several-fold, in relation to what it was 60 years ago.

My father Carlos Lage, who was Laboratorios Dispert technical manager decided to leave the company. Part of the agreement was that Laboratorios Dispert would not produce legume inoculants and that he would continue producing them in his new company, Lage y Cía. S.A. that he founded in 1978. The first inoculants Lage y Cía. S.A. produced were formulated on a non-sterile peat carrier, which was the technology available in those times. A few years later Prof. Labandera attended a congress in which researchers showed the improvements when using carriers with low numbers of contaminants, so immediately after Labandera´s return, SMICL suggested that the peat should be sterilised in order to obtain better quality inoculants. Also concentration standards were raised: inoculants should contain more than 5x108 viable cells per gram when produced and more than 1x108 viable cells by expiry date. A year later, the standards were upgraded to more than 1x109 viable cells per grams when produced and more than 1x108 viable cells at expiry date. But as soon as the company increased sales, another sterilisation method was required. In 1985 two other companies were in the market and SMICL suggested the three companies to use gamma-radiation treatment for the peat in order to be able to sterilise larger amounts of it and simultaneously increased again the standard that an inoculant should achieve to be allowed to be delivered to the market, setting a minimum of 2x109 viable cells per gram when produced and more than 1x109 viable cells by the expiry date, free of contaminants. These standards are still in force and to require more than 1 x 109 Rhizobium by expiry date, setting Uruguay as the country with highest concentration standard in the world at expiry date.

Soyabean area started increasing in 2002 and large farmers demanded a more practical inoculation system as peat based products were not easy to use. We decided to develop a liquid formulation for soyabeans that could simplify the inoculation process. SMICL gave instructions that if a company decided to launch a liquid formulation, it could not be produced in large scales and initially allowed each company to introduce inoculants for no more than 1000 ha. SMICL set the rate of 150 ml of inoculant to treat 50 kg of soyabean seeds. The idea was that SMICL could trace the liquid inoculants at the distributors warehouses in order to control their quality during the whole soyabean season.

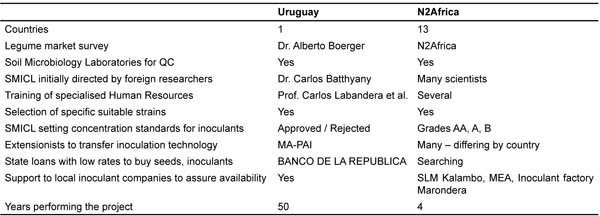

If we compare the process between Uruguayan SMICL and N2AFRICA, we can find in Table 1 that the process has been almost identical, but with very important aspects to remark in the African process: N2Africa has attempted in 4 years almost the same activities (and surely in major quantities) that we succeeded in achieving over almost 5 decades.

Since 2002, we have delivered millions of inoculum packets to Argentina, Brazil, Paraguay, Bolivia, South Africa and Zambia. This year, small amounts for trial purposes have been sent to Ghana, Central and North America.

|

It has not been easy at all to export when you come from a country that most people have hardly heard about and that is only known thanks to our football players Suarez, Cavani and Forlán. But the job of SMICL giving guidance in what regards to kind of carrier, suitable sterilising techniques, setting standards for absence of contaminants and a concentration 10 times higher than our competitors, helped us improve our quality to match the global players´ products and helped us to open new markets for our products. Being an independent inoculant company and also having a little bit of good luck have been the reasons of finding suitable partners as Microbial Solutions in South Africa and Albida Agriculture in Zambia. To match with delighting people in both countries has been the principal factor to start business and another important issue is that they marketed other biological products before importing our inoculants, which I consider the basic characteristic a distributor should have to properly deliver the inoculants to the market. It is not easy to think "Bio" when you are a chemical company. |

Photo 2: Left to right: Martin Lage, Fred Nandala, manager of Wangwa Farms in Chisamba, Zambia and George Allison, Director Albida Agriculture

|

Having met the most suitable partners and their continuous effort to introduce LIKUIQTM inoculants has been the reason for raising sales each season. We try to visit them at least once a year or receive them in Uruguay, in order to adjust order details and also give technical support.

|

Photo 3: Field trial performed by Microbial Solutions in South Africa, comparing LIKUIQ (stripes in dark green) against another inoculant (light green) |

Ghana is a completely different story. I thought that attending an important agrochemical congress in Accra in 2012 would help us find at least one "Bio" distributor for many different countries. Now, it is obvious for me to say that I was in the wrong place as I could not find any distributor interested in inoculants. Incredibly, a few months ago, our Italian importer started doing business with TT Brothers, a company located in Tema, Ghana and has asked us to deliver them a small amount of LIKUIQTM for soyabeans and GRAMINOSOILTM, our Azospirillum based inoculant for maize.

|

Our expansion in Africa will be directly depend on our ability to find suitable new distributors. The degree of success of those inoculant companies in each country depends on several factors: commercial, regulatory, technical and technological. Nevertheless, the importance given by each government to the diffusion of the technology and to assure that farmers receive a high quality inoculant is the reason why there is such a difference in inoculated/uninoculated areas in most countries. It is important to emphasize that in those of them where the inoculation technology is successful, with a high level of adoption in commercial legume pastures or crops, there has been a permanent and intimate relation between researchers, universities, public entities, extensionists, farmers and the private inoculant factories. Cooperative efforts among all these sectors permit a dynamic development of the BNF research work, which allows enormous economic benefits in productive terms.

Today and the same as in Africa, soyabeans are the legume crop in South America to which most rhizobiological work has been dedicated. In relation to other crops as groundnuts and beans, the inoculation practice does not have high levels of adoption in nearby countries, and in most situations the reason is not the lack of positive productive responses. Although we may consider there is great research work dedicated to it in relation to BNF in other crops, it has not been transferred to the productive sector (farmers) in the same manner as it occurred with soyabeans.

|

It seems to me that the Uruguayan inoculant industry developed based in some solid pillars that have allowed us to grow locally and also exporting all around the world. N2Africa´s pillars are exactly the same, so I am sure that in a near future, new African inoculant companies will be in the market.

Pedro Lage, E-mail: lage@lageycia.com |

|